DISCOVER BOLIDT

THE WORLD OF BOLIDT KNOWNS NO LIMITS

No Limits

The world of Bolidt knows no limits. You will be working for a company that operates around the world in many different fields. Every day we come up with unique solutions in thermosetting synthetics: solutions that are best for our customers.

Bolidt’s motto is ‘Everything under one roof’. This means that our capabilities cover the entire value chain. From development and production to sales and application. The Bolidt Innovation Center was opened in 2019, the beating heart of Bolidt Campus. Here we will inspire many visitors each year by immersing them in the world of Bolidt.

Our playgrounds

Bolidt covers two million square metres with synthetic systems in various fields of application each year. From floor finishes in chicken hatcheries to surface courses on roads and bridges. From liquid-tight flooring in hospitals to durable decking on superyachts.

Our application teams are flown out to projects around the world. The design floors at the Olympic swimming pool in Beijing and in the European Parliament in Brussels are from Bolidt. Just like the ones in the London Science Museum and the King Abdulaziz Center for World Culture in Saoedi-Arabië.

Every year, we fit enormous cruise ships with new layers of decking. Aboard the world’s largest cruise ship Symphony of the Seas, we installed 20,000 m2 of decks that cover millions of feet each year. And we even installed a Ferrari racetrack aboard the Norwegian Joy. The decks on board the largest and strongest semi-submersible offshore vessel Sleipnir are also from Bolidt.

Not only are we very active globally, but also in the Netherlands. The floor finishes in the Old Luxor theatre in Rotterdam were made by Bolidt. We installed about 60,000 m2 of floor and wall finishes in the Erasmus Medical Centre. We have worked at the highest levels, on the Euromast and underground, in numerous car parks including the world’s largest bike parking facility under Hoog Catharijne in Utrecht. All major bridges in the Netherlands feature durable surface courses from Bolidt. Our shock-resistant flooring systems strengthen the structure of Royal Netherlands Navy vessels. The flooring in restaurant SushiSamba and in Het Landhuis op de Hoge Veluwe: also from Bolidt.

It is not only what we do that makes us unique, but also how we do it: Bolidt does everything itself. We are the only company in our industry to control the entire value chain. From the purchase of raw materials, the conception, development and production of thermosetting synthetics to their installation throughout the world. We even build our own machines, which have enabled us, for instance, to resurface the Rheinbücke Maxau in Karlsruhe in record time. Innovating is in our DNA. That makes us very proud and the competition a little bit jealous.

Bolidt is active in many areas. Take a look at our website to find out which segments we operate in.

Vitality

Bolidt helps you to be as energetic as possible, both physically and mentally. You can cycle up Mont Ventoux with your colleagues or enjoy a game of chess, whichever you prefer. Vitality is in little things, but we are committed to it in a big way.

At Bolidt, we are never idle. We are always working on new ideas, plans and innovations. You need to keep moving to stay healthy. That is why we pay so much attention to vitality. When you are healthy, you have more energy. More focus. More fun. Fit employees are also more creative and inventive. It is often during or after doing sports that brilliant ideas are born. Exactly what we need at Bolidt. Vitality is in little things. Standing up in meetings, for instance. Having a healthy lunch. Or walking over to a colleague instead of sending an e-mail. But we are also committed to vitality in a bigger way. With a special vitality programme. This earned us the ‘Most Energetic Company in South Holland’ award in 2016.

Our office includes a high-tech fitness room where you can work out under the guidance of a professional trainer. There are workshops about exercise, nutrition and mind vitality. We also have various sports teams. Join the Bolidt Running Team and get in shape for the Inner Circle Run, which is sponsored by Bolidt. Head for the Alps with the Bolidt Cycling Team. IAnyone who wants to can have a personal check-up. So that you know what condition your health is in. The Bolidt Vitality app gives you 24/7 access to your own personal trainer and an overview of your achievements. Sports bring people together. As a purchaser you may suddenly find yourself boxing a chemical engineer. Or cycling side by side with the CEO towards the summit of La Redoute. The result? Lunch conversations are no longer just about work. Participating in joint sports activities contributes to a good atmosphere at work and strengthens team spirit.

Flexibility

As an innovative company we are flexible by definition. It shows in the way our office spaces look and in the way we work. Looking across boundaries is part of your everyday work. Bolidt does things differently. Flexibility is our middle name. Our headquarters have a sleek modern interior, with a design aesthetic and attention to detail. You can work anywhere in the building: in the open-plan office areas, in the brasserie and on the visually and acoustically shielded Vitra office furniture. The mini call centre allows for undisturbed phone calls. That freedom to choose where you work stimulates interaction – the very reason why we prefer not to drink coffee at our desk, but in the coffee areas. Perfect for striking up a conversation with a colleague. Together you may come up with a great idea.

INNOVATION

Always working on new ideas. Looking for areas where we can improve. Innovating is in our DNA. We do it in our innovation centre, but also in the coffee areas and at the lunch table. Of course, Bolidt is known for its flooring, marine decking and surface courses. But what we really do is develop innovative applications for thermosetting synthetics. We have an innate drive to constantly search for new ideas. Always playing with the principle: from liquid to solid. Our curiosity has resulted in thermosetting synthetics being applied in different ways. Additionally, we have used the material to develop a wide range of sustainable solutions.

EDUCATION

Innovation starts with knowledge development. To improve themselves and the company, Bolidt’s employees receive continuous education and training. The founders of Bolidt once started out with guts and a taste for adventure. That spirit is still alive in our company today. Do you have a good idea and want to develop something new? At Bolidt you will get the opportunity to put together a plan.

The open culture at Bolidt makes it possible to discuss innovations, successes and dreams at any moment of the day: in the coffee areas, in the culture shed or over a healthy lunch in the Brasserie. During the ‘Week of Innovation’, which is organised each year, employees also get the opportunity to share the innovation they are working on with their colleagues.

This is how progress and entrepreneurship become visible and tangible to everyone. Based on the same idea, monthly ‘Lunch & Learn sessions’ are held at Bolidt for employees to update each other on innovations. These may be new ideas from within Bolidt or innovations developed by customers that we can respond to. Knowledge development is an everyday priority in an innovative company like Bolidt. Employees are continually educated and trained. Installing synthetic flooring, decking and surface courses is specialist work and only entrusted to highly skilled professionals. Our installers therefore go through an extensive course at the Bolidt Academy. Here you learn everything about the properties of our synthetic systems, processing the materials, the suitability of the substrate and the impact of climatic conditions.

As may be clear by now, we enjoy educating people. That is why trainees are always welcome at Bolidt.

LEAN

Bolidt is learning to work and think LEAN. This philosophy is implemented by employees from across the organisation, who all represent a particular discipline. In this area, too, we provide continuous training to ensure that the teams within Bolidt are goal oriented, work efficiently and enjoy what they are doing. All managers at Bolidt follow the Master in Business Learning (MBL) course at the Arpa Learn Institute. This 4-year course teaches managers how to bring the LEAN ideas into practice and build a learning organisation.

KNOWINGO

At Bolidt, education is not only about individual learning, but also about increasing the knowledge of the collective.

Developed especially with this in mind, the knowledge app ‘Knowingo’ is an e-learning app based on artificial intelligence that offers a fun way to enhance your knowledge. By using this intelligent platform employees get to know more about Bolidt, the synthetic systems, their colleagues and our customers.

The app also encourages interaction: if you don’t know something, you just ask a colleague.

WORKING SAFELY

At Bolidt, education also means working safely. Removing all risks and preventing incidents. Our health and safety systems have been certified according to the Dutch Safety, Health and Environment Checklist Contractors (VCA). That means that we have a structural and systematic approach to ensuring safety in the workplace. With the VCA* certificate Bolidt demonstrates that all safety, health and environment standards are being met during our projects throughout the world. We constantly strive for a safer working environment. Not only for our own employees, but also for the subcontractors we employ. That is why we also hold the VCA** certificate. This guarantees that the professionals we hire also work in a safety conscious manner.

GREENDOTS

GreenDots shows with concrete facts and figures what Bolidt has been working on for many years: growing as a company and at the same time increasing our social impact and reducing our environmental impact. By making maximum use of natural, non-scarce resources, for instance. Keeping the entire value chain in-house, we constantly look for the most sustainable solutions.

We also invest in the development, safety and vitality of our employees to create a safe and challenging work environment. Our engagement in the future is visible in every aspect of our business. GreenDots provides insight into what this means for people and the environment. For more details, take a look at: www.greendots.eu.

Experience

Our new entrance. Our showpiece. The Bolidt Innovation Center allows our business partners to familiarise themselves with the versatility of Bolidt. An inspiring experience. In the Bolidt Innovation Center we engage in dialogue with customers, co-makers, knowledge institutions and start-ups about new applications for synthetics. Open source, open mind: nothing is impossible. This is where we realise dreams in synthetics. Together with the many visitors.

I’m always looking for the right chemistry between a candidate and the team

RECRUITER

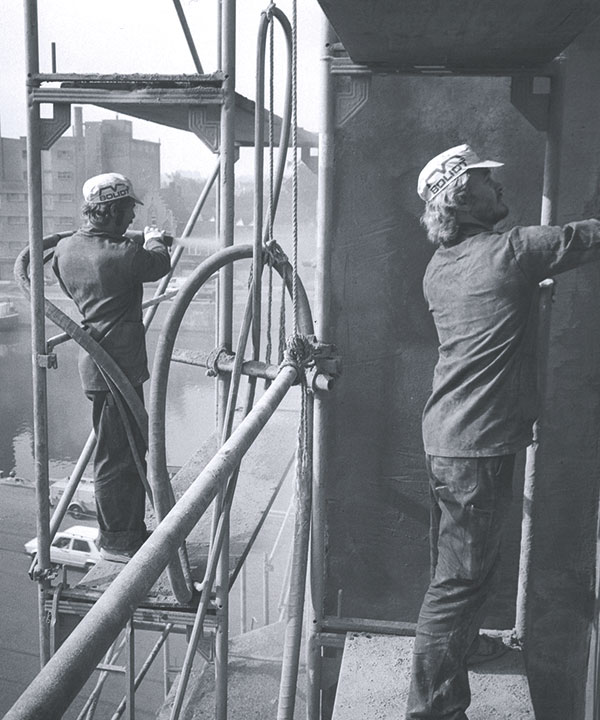

Legacy

From a shed in Zwijndrecht to a company with 250 dedicated professionals. The urge to renew takes Bolidt all over the world. Feel free to come along. 1964: Two employees of paint manufacturer Sikkens start their own business. Rather than just using synthetics as paint, it must be possible to do more with them. Replace conventional materials like wood and steel, for instance. Think of applications that nobody has thought of yet. From a shed in Zwijndrecht, the two want to conquer the world. Starting with the Netherlands.